電(dian)容(rong)器的(de)常見失效(xiao)模(mo)式有(you):擊穿、開路、電(dian)參數(shu)變化(包括電(dian)容(rong)量(liang)超差、損耗角正(zheng)切值增(zeng)大、絕緣性能(neng)下降(jiang)或(huo)漏電(dian)流上下班升等)、漏液、引線腐(fu)蝕或(huo)斷裂、絕緣子(zi)破裂或(huo)表面飛(fei)弧等.引起電(dian)容����(rong)器失效(xiao)的(de)原因(yi������n)是多種多樣(yang)的(de).各(ge)類電(dian)容(rong)器的(de)材料(liao)、結構、制造工(gong)藝、性能(neng)和使用環境各(ge)不相同,失效(xiao)機理也各(ge)不一樣(yang).

各種�����������(zhong)常(chang)見失(shi)效模式的主(zhu)要(yao)產生機理歸(gui)納如(ru)下.

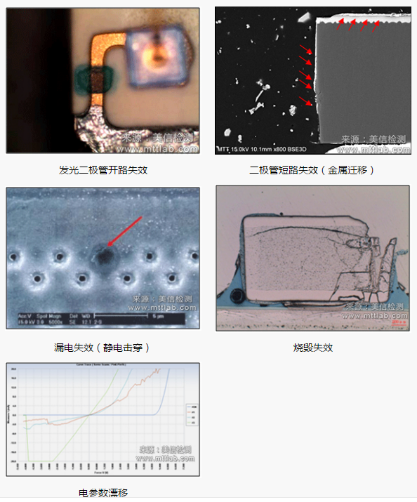

1、常見的七種失效模式

(1) 引(yin)起電容器(qi)擊(ji)穿的(de)主要失(shi)效(xiao)機理

① 電(dian)介(��������jie)質(zhi)材料有疵點或(huo)缺(que)陷(xian),����或(huo)含有導電(dian)雜(za)質(zhi)或(huo)導電(dian)粒子(zi);

② 電(dian)介質的電(dian)老化與熱老化;

③ 電介質內部的電化(hua)學反應;

④ 銀離子遷移;

⑤ 電(dian��������)(dian)介質在電(dian)(dian)容器制造過程(cheng)中受到(dao)機械損����(sun)傷;

⑥ 電(dian)介質分子結(jie)構改變;

⑦ 在高(gao)濕(shi)度或低氣壓環境中極間飛(fei)弧(hu);

⑧ 在機械應力作用下電介質瞬時短(duan)路(lu).

(2) 引(yin)起(qi)電容(rong)器開路的主要(yao)失效機理

① 引線(xian)部(bu)位發生“自愈���������“,使(shi)電極與(yu)引出線�����(xian)絕(jue)緣;

② 引出線與電(dian)極(ji)接觸表面(mian)氧化,造成低電(dian)平開路(lu);

③ 引出(chu)線與電極接觸(chu)不良;

④ 電解電容器陽極引出箔(bo)腐(fu)蝕斷裂;

⑤ 液體工(gong)作臺電解質(zhi)干涸(he)或凍結;

⑥ 機(ji)械應力作用(yong)下電介質瞬時開(kai)路.

(3) 引(yin)起電容器電參數惡化的主要失效機(ji)理(li)

① 受潮或表面污(wu)染;

② 銀離子遷移;

③ 自愈效應;

④ 電介質電老化與(yu)熱老化;

⑤ 工作電(dian)解液揮發(fa)和變(bian)稠;

⑥ 電極腐蝕;

⑦ 濕式電解電容器中電介(jie)質腐蝕;

⑧ 雜質與有害離子的(de)作用;

⑨ 引出線(xian)和(he)電極的接觸電阻增(zeng)大.

(4) 引(yin)起電(dian)容器漏液的主(zhu)要原(yuan)因

① 電場作(zuo)用下(xia)浸漬料(lia�����o)分解放氣(qi)使殼內氣(qi)壓一(yi)升(sheng);

② 電(dian)容(rong)器金屬外(wai����)殼與密封(feng)蓋焊(han)接(jie)不佳;

③ 絕緣了(le)與外殼或引線(xian)焊(han)接不(bu)佳;

④ 半(ban)密(mi)封(feng)電容(rong)器機械密(mi)封(feng)不良;

⑤ 半密封電容器引線表面不夠光(guang)潔;

⑥ 工作電(dian)解液(ye)腐蝕焊(han)點(dian).

(5) 引起(qi)電(dian)容器引線腐蝕(shi)或斷裂的主(zhu)要(yao)原因

① 高(gao)溫度(du)環境中電場作(zuo)用下產(chan)生電化學腐蝕;

② 電解(jie)液沿(yan���)引線(xian)滲�������(shen)漏,使引線(xian)遭受(shou)化學腐蝕;

③ 引線在電(dian)容器(qi)制造過程(cheng)中受到機械損(sun)傷(shang);

④ 引線的(de)機械(xie)強度不夠.

(6) 引起(qi)電容(rong)器絕緣(yuan)子破(po)裂的主(zhu)要原因

① 機械損傷;

② 玻璃粉絕(jue)緣子燒結(jie)過(guo)程中殘留熱(re)力過(guo)大;

③ 焊接溫度過高或(huo)受熱不(bu)均勻.

(7) 引起(qi)絕(jue)緣子表面(mian)飛弧的主要原因(yin)

① 絕(jue)(jue)緣了表面(mia�������n)受潮,使(shi)表面(mian)絕(jue)(jue)緣電阻下降;

② 絕緣了設計(ji)不合理(li)

③ 絕緣了選用不當

④ 環境氣壓過低.

電(dian)(dian)容器擊穿、開路(lu)、引線斷裂、絕緣(yuan)了(le)破裂等使(sh�������i)電(di�����an)(dian)容器完全失(shi)(shi)去工作能力的失(shi)(shi)效(xiao)屬致命(ming)性失(shi)(shi)效(xiao),其余一些失(shi)(shi)效(xiao)會使(shi)電(dian)(dian)容不能滿足使(shi)用要(yao)求,并(bing)逐漸向致命(ming)失(shi)(shi)效(xiao)過渡;

電容(rong)器在工作(zuo)應(ying)力與環境應(ying)力綜合(he)作(zuo)用下,工作(zuo)一(yi)(yi)(yi)段(duan)�����時間后(hou),會(hui)分別或同(tong)時產生(sheng)某些失(shi)效模式.同(tong)一(yi)(yi)(yi)失(shi)效模式有多種(zhong)失(shi)效機(ji)(ji)理(li),同(tong)一(yi)(yi)(yi)失(shi)效機(ji)(ji)理(li)又可(ke)產生(sheng)多種(zhong)失(shi)效模式.失(shi)效模式與失(shi)效機(ji)(ji)理(li)之(zhi)間的關系(xi)不是(shi)一(yi)(yi)(yi)一(yi)(yi)(yi)對應(ying)的.

2、電容器失效機理(li)分析

(1)、潮濕對電參數惡化的影響

空氣中濕度過高(gao)時,水膜凝聚在電(dian)(dian)容器外殼表(biao)面,可(ke)使電(dian)(dian)容器的(de)(de)(de)表(biao)面絕緣(yuan)電(dian)(dian)阻下(xia)降(jiang).此處(chu),對于(yu)(yu)半密封結構(gou)電(dian)(dian)容器來說,水分還(huan)可(ke)滲(shen)透到電(dian)(dian)容器介(jie)質內部(bu),使電(dian)(dian)容器介(jie)質的(de)(de)(de)絕緣(yuan)電(dian)(dian)阻絕緣(yuan)能(neng)(neng)力下(xia)降(jiang).因此,高(gao)溫(wen)、高(gao)濕環境對電(dian)(dian)容器參數惡化的(de)(de)(de)影響極(ji)為顯著.經烘(hong)(ho������ng)干(gan)去濕后電(dian)(dian)容器的(de)(de)(de)電(dian)(dian)性能(neng)(neng)可(ke)獲改善,但是水分子(zi)電(dian)(dian)解的(de)(de)(de)后果是無(wu)法(fa)根除(chu)的(de)(de)(de).例如:電(dian)(dian)容器工作(zuo)于(yu)(yu)高(gao)溫(wen)條(tiao)件下(xia),水分子(zi)在電(dian)(dian)場作(zuo)用(yong)下(xia)電(dian)(dian)解為氫離子(zi)(H+)和氫氧根離子(zi)(OH-),引線根部(bu)產生電(dian)(dian)化學腐蝕(shi).即使烘(hong)(hong)干(gan)去濕,也不可(ke)能(neng)(neng)引線復原.

(2)、銀離子遷移的后果

無機(ji)(ji)介(jie)質(zhi)(zhi)電(dian)容器(qi)(qi)多半采用(yong)銀(yin)(yin)電(dian)極,半密(mi)封電(dian)容器(qi)(qi)在(zai)(zai)高溫條件下工作時,滲入電(dian)容器(qi)(qi)內部的水(shui)分子(zi)產生(sheng)(sheng)(sheng)電(dian)解.在(zai)(zai)陽極產生(sheng)(sheng)(sheng)氧(yang)化(hua)反(fan)應,銀(yin)(yin)離(li)子(zi)與(yu)氫氧(yang)根離(li)子(zi)結合(he)生(sheng)(sheng)(sheng)成(cheng)氫氧(yang)化(hua)銀(yin)(yin).在(zai)(zai)陰極產生(sheng)(sheng)(sheng)還(huan)原反(fan)應、氫氧(yang)化(hua)銀(yin)(yin)與(yu)氫離(li)子(zi)反(fan)應生(sheng)(sheng)(sheng)成(cheng)銀(yin)(yin)和水(shui).由于電(dian)極反(fan)應,陽極的銀(yin)(yin)離(li)子(zi)不(bu)斷向陰極還(huan)原成(cheng)不(bu)連續金屬銀(yin)(yin)粒,靠水(shui)膜連接成(cheng)樹狀向陽極延伸(shen).銀(yin)(yin)離(li)子(zi)遷移不(b����u)僅發(fa)生(sheng)(sheng)(sheng)在(zai)(zai)無機(ji)(ji)介(jie)質(zhi)(zhi)表面(mian),銀(yin)(yin)離(li)子(zi)還(huan)能擴(kuo)散到無機(ji)(ji)介(jie)質(zhi)(zhi)內部,引起漏(lou)電(dian)流(liu)增大,嚴重時可(ke)使兩個(ge)銀(yin)(yin)電(dian)極之間(jian)完全(quan)短(duan)路,導致電(dian)容器(qi)(qi)擊(ji)穿.

銀離子遷移可嚴重破壞(huai)正電(dian)極表面銀層,引線(xian)焊點(dian)與電(dian)極表面銀層之(zhi)間,間隔著(zhu)具(ju)有半導體性(xing)質的(de)氧化(hua)銀,使無機介質電(dian)容器的(de)等效串聯電(dian)阻增大(da),金屬部分損耗(hao)增加,電(dian)容器的(de)損耗(hao)角正切(�����qie)值(zhi)顯著������(zhu)上升.

由于正電(dian)(dian)(dian)極(ji)有效(xiao)面(mian)積減(jian)小,電(dian)(dian)(dian)容(rong)器的(de)電(dian)(dian)(dian)容(rong)量會因(yin)此(ci)而下降(jiang).����表面(mian)絕緣電(dian)(dian)(dian)阻則因(yin)無機介������(jie)質電(dian)(dian)(dian)容(rong)器兩(liang)電(dian)(dian)(dian)極(ji)間(jian)介(jie)質表面(mian)上存在氧化銀半導體而降(jiang)低.銀離子(zi)遷(qian)移嚴重時,兩(liang)電(dian)(dian)(dian)極(ji)間(jian)搭起樹枝狀的(de)銀橋,使電(dian)(dian)(dian)容(rong)器的(de)絕緣電(dian)(dian)(dian)阻大(da)幅度下降(jiang).

綜上所(suo)述,銀離子遷移不(bu)僅會使非密封無機介(jie)質(zhi)電容(rong)器(qi)電性能惡(e)化,而(er)且可能引起介(jie)質(zhi)擊(ji)穿場(chang)強下(xia)降,最(zui)后導致電容(ron������g)器(qi)擊(ji)穿.

值(zhi)得一提的(de)(de)(de)是:銀(yin)電(dian)(dian)極低頻陶(tao)瓷(ci)獨石電(dian)(dian)容器(qi)由于銀(yin)離子遷(qian)(qian)移而引起失效的(de)(de)(de)現象比其他類型的(de)(de)(de)陶(tao)瓷(ci)介(jie)(jie)質(zhi)(zhi)電(dian)(dian)容器(qi)嚴重得多,原因在于這種(zhong)電(dian)(dian)容器(qi)的(de)(de)�����(de)一次燒成(cheng)工藝與(yu)(yu)多層(ceng)疊(die)片結(jie)構.銀(yin)電(dian)(dian)極與(yu)(yu)陶(tao)瓷(ci)介(jie)(jie)質(zhi)(zhi)一次燒也過程中,銀(yin)參與(yu)(yu)了陶(tao)瓷(ci)介(jie)(jie)質(zhi)(zhi)表(biao)(biao)面(mian)的(de)(de)(de)固相反應,滲入了瓷(ci)-銀(yin)接(jie)觸處形成(cheng)界面(mian)層(ceng).如果陶(tao)瓷(ci)介(jie)(jie)質(zhi)(zhi)不夠致密,則水分滲入后,銀(yin)離子遷(qian)(qian)移不僅可以在陶(tao)瓷(ci)介(jie)(jie)質(zhi)(zhi)表(biao)(biao)面(mian)發生(sheng),還可能穿透(tou)陶(tao)瓷(ci)介(jie)(jie)質(zhi)(zhi)層(ceng).多層(ceng)疊(die)片結(jie)構的(de)(de)(de)縫隙較多,電(dian)(dian)極位置(zhi)不易(yi)精確,介(jie)(jie)質(zhi)(zhi)表(biao)(biao)面(mian)的(de)(de)(de��������)留邊量小,疊(die)片層(ceng)兩端(duan)涂覆外電(dian)(dian)極時(shi)銀(yin)漿滲入縫隙,降(jiang)低了介(jie)(jie)質(zhi)(zhi)表(biao)(biao)面(mian)的(de)(de)(de)絕緣電(dian)(dian)阻(zu),并(bing)使(shi)電(dian)(dian)極之(zhi)間的(de)(de)(de)路徑縮(suo)短,銀(yin)離子遷(qian)(qian)移時(shi)容易(yi)產生(sheng)短路現象.

(3)、高濕度條件下陶瓷電容器擊(ji)穿機(ji)理

半密封陶瓷(ci)電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)(qi)在高濕(shi)度環境條件下工作(zuo)時,發生(sheng)(sheng)(sheng)擊(ji)穿(chuan)(chuan)(chuan)(chuan)失效(xiao)是(shi)比較普(pu)遍的嚴重問(wen)題(ti).所發生(sheng)(sheng)(sheng)的擊(ji)穿(chuan)(chuan)(chuan)(chuan)現象大(da)約可(ke)(ke)以分(fen)為(wei)介質擊(ji)穿(chuan)(chuan)(chuan)(chuan)和表面(mian)(mian)極間(jian)飛弧擊(ji)穿(chuan)(chuan)(chuan)(chuan)兩類.介質擊(ji)穿(chuan)(chuan)(chuan)(chuan)按發生(sheng)(sheng)(sheng)時間(jian)的早(zao)晚又(you)可(ke)(ke)分(fen)為(wei)早(zao)期擊(ji)穿(chuan)(chuan)(chuan)(chuan)與老化(hua)擊(ji)穿(chuan)(chuan)(chuan)(chuan)兩種.早(zao)期擊(ji)穿(chuan)(chuan)(chuan)(chuan)暴露了電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)介質材料與生(sheng)(sheng)(sheng)產工藝方(fang)面(mian)(mian)存在的缺陷(xian)(xian),這些(xie)缺陷(xian)(xian)導致(zhi)陶瓷(ci)介質電(dian)(dian)(dian)(dian)強度顯著(zhu)降(jiang)低(di),以致(zhi)于(yu)在高濕(shi)度環境中電(dian)(dian)(dian)(dian)場作(zuo)用(yong)下,電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)(qi)在耐壓(ya)試驗過程(cheng)中或(huo)工作(zuo)初期,就產生(sheng)(sheng)(sheng)電(dian)(dian)(dian)(dian)擊(ji)穿(chuan)(chuan)(chuan)(chuan).老化(hua)擊(ji)穿(chuan)(chuan)(chuan)(chuan)大(da)多屬于(yu)電(dian)(di�������an)(dian)(dian)化(hua)學擊(ji)穿(chuan)(chuan)(chuan)(chuan)范疇.由(you)于(yu)陶瓷(ci)電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)(qi)銀的遷(qian)移(yi),陶瓷(ci)電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)(qi)的電(dian)(dian)(dian)(dian)解老化(hua)擊(ji)穿(chuan)(chuan)(chuan)(chuan)已成為(wei)相當(dang)普(pu)遍的問(wen)題(ti).銀遷(qian)移(yi)形成的導電(dian)(dian)(dian)(dian)樹枝狀物,使漏(lou)電(dian)(dian)(dian)(dian)流局(ju)部(bu)增大(da),可(ke)(ke)引起熱擊(ji)穿(chuan)(chuan)(chuan)(chuan),使電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)(qi)斷裂(lie)(lie)或(huo)燒毀(hui).熱擊(ji)穿(chuan)(chuan)(chuan)(chuan)現象多發生(sheng)(sheng)(sheng)在管形或(huo)圓(yuan)片形的小型瓷(ci)介電(dian)(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)(qi)中,因為(wei)擊(ji)穿(chuan)(chuan)(chuan)(chuan)時局(ju)部(bu)發熱厲害,較薄的管壁或(huo)較小的瓷(ci)體容(rong)(rong)(rong)易(yi)燒毀(hui)或(huo)斷裂(lie)(lie).

此(ci)外,以二(er)氧化(hua)鈦為主的(de)(de)陶(tao)(tao)(tao)瓷介(jie)質中,負荷條(tiao)件下(xia)還(huan)可能產生(sheng)二(er)氧化(hua)鈦的(de)(de)還(huan)原反應(ying),使鈦離(li)子由四價變(bian)為三價.陶(tao)(tao)(tao)瓷介(jie)質的(de)(de)老化(hua)顯(xian)著降低了電(dian)(dian)容(rong)(rong)器的(de)(de)介(jie)電(dian)(dian)強度,可能引起(qi)電(dian)(dian)容(rong)(rong)器擊穿.因此(ci),這種陶(tao)(tao)(tao)瓷電(dian)(dian)容(rong)(rong)�������器的(de)(de)電(dian)(dian)解擊穿現象(xiang)比不含(han)二(er)氧化(hua)鈦的(de)(de)陶(tao)(tao)(tao)瓷介(jie)質電(dian)(dian)容(rong)(rong)器更加嚴重(zhong).

銀離(li)子(zi)(zi)遷(qian)移使電(dian)(dian)(dian)(dian)容器極間(jian)(jian)邊緣(yuan)電(dian)(dian)(dian)(dian)場發(fa)生(sheng)(sheng)(sheng)嚴(yan)重畸變,又因高濕度環(huan)(huan)境(jing)中(zhong)陶瓷介(jie)質表(biao)(biao)面(mian)(mian)(mian)凝有水膜(mo),使電(dian)(dian)(dian)(dian)容邊緣(yuan)表(biao)(biao)面(mian)(mian)(mian)電(dian)(dian)(dian)(dian)暈放電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)壓顯著(zhu)下(xia)降,工作(zuo)條件下(xia)產生(sheng)(sheng)(sheng)表(biao)(biao)面(mian)(mian)(mian)極間(jian)(jian)飛弧現象(xiang).嚴(yan)重時導致電(dian)(dian)(dian)(dian)容器表(biao)(biao)面(mian)(mian)(mian)極間(jian)(jian)飛弧擊(ji)穿(chuan).表(biao)(biao)面(mian)(mian)(mian)擊(ji)穿(chuan)與電(dian)(dian)(dian)(dian)容結構(gou)、極間(jian)(jian)距離(li)、負(fu)荷電(dian)(dian)(dian)(dian)壓、保護層的疏(shu)水性與透濕性等(deng)因素有關.主(zhu)要就是邊緣(yuan)表(biao)(biao)面(mian)(mian)(mian)極間(jian)(jian)飛弧擊(ji)穿(chuan),原因是介(jie)質留邊量(liang)較(jiao)小,在潮濕環(huan)(huan)境(jing)中(zhong)工作(zuo)時銀離(li)子(zi)(zi)遷(qian)移和(he)表(biao)(biao)面(mian)(mian)(mian)水膜(mo)形成使電(dian)(dian)(dian)(dian)容器邊緣(yuan)表(biao)(biao)面(mian)(mian)(mian)絕緣(yuan)電(dian)(dian)(dian)(dian)阻顯著(zhu)下(xia)降,引起電(dian)(dian)(dian)(dian)暈放電(dian)(dian)(di�������an)(dian),最終導致擊(ji)穿(chuan).高濕度環(huan)(huan)境(jing)中(zhong)尤其嚴(yan)重.由于銀離(li)子(zi)(zi)遷(qian)移的產生(sheng)(sheng)(sheng)與發(fa)展需要一段(duan)時間(jian)(jian),所以(yi)在耐壓試驗初期(qi),失(shi)效模式(shi)以(yi)介(jie)質擊(ji)穿(chuan)為主(zhu),直(zhi)到試驗500h以(yi)后,主(zhu)要失(shi)效模式(shi)才過渡為邊緣(yuan)表(biao)(biao)面(mian)(mian)(mian)極間(jian)(jian)飛弧擊(ji)穿(chuan).

(4)、高(gao)頻精(jing)密(mi)電(dian)(dian)容(rong)器(qi)的低電(dian)(dian)平(ping)������失效機理

云(yun)(yun)母(mu)是(shi)(shi)(shi)一(yi)種較理想的(de)電(dian)(dian)(dian)容器(qi)(qi)(qi)介質(zhi)材(cai)料,具有很高(gao)的(de)絕緣(yuan)性(xing)能,耐(nai)高(gao)溫,介質(zhi)損(sun)(sun)耗(hao)小(xiao),厚度可薄(bo)達25微米.云(yun)(yun)母(mu)電(dian)(dian)(dian)容器(qi)(qi)(qi)的(de)主要(yao)優(you)點是(shi)(shi)(shi)損(sun)(sun)耗(hao)小(xiao),頻率穩定性(xing)好(hao)、分布電(dian)(dian)(dian)感小(xiao)、絕緣(yuan)電(dian)(dian)(dian)阻大,特別適合在高(gao)頻通信電(dian)(dian)(dian)路中(zhong)用(yong)做精密電(dian)(dian)(dian)容器(qi)(qi)(qi).但(dan)是(shi)(shi)(shi),云(yun)(yun)母(mu)資源有限,難于(yu)推(tui)廣使用(yong).近數十年內(nei),有機薄(bo)膜(mo)電(dian)(dian)(dian)容器(qi)(qi)(qi)獲得迅速發展,其中(zhong)聚苯乙(yi)(yi)烯薄(bo)膜(mo)電(dian)(dian)(dian)容器(qi)(qi)(qi)具有損(sun)(sun)耗(hao)小(xiao)、絕緣(yuan)電(dian)(dian)(dian)阻大、穩定性(xing)好(hao)、介質(zhi)強度高(gao)等優(you)點.精密聚苯乙(yi)(yi)烯電(dian)(dian)(dian)容器(qi)(qi)(qi)可代替云(yun)(yun)母(mu)電(dian)(dian)(dian)容器(qi)(qi)(qi)用(yong)于(yu)高(gao)頻電(dian)(dian)(dian)路.需要(yao)說明(ming)的(de)是(shi)(shi)(shi):應用(yong)于(yu)高(gao)頻電(dian)(dian)(dian)路中(zhong)的(de)精密聚苯乙(yi)(yi)烯電(dian)(dian)(dian)容器(qi)(qi)(qi),一(yi)般(ban)采用(yong)金屬箔極板,以提高(gao)絕緣(yuan)電(dian)(dian)(����dian)阻與降低損(sun)(sun)耗(hao).

?? 電(dian)(dian)容(rong)(rong)(rong)(rong)器(qi)(qi)的低(di)電(dian)(dian)平(ping)失(shi)(shi)效(xiao)是(shi)20世(shi)紀(ji)60年代以(yi)來出(chu)現(xian)的新問題.低(di)電(dian)(dian)平(ping)失(shi)(shi)效(xiao)是(shi)指電(dian)(dian)容(rong)(rong)(rong)(rong)器(qi)(qi)在低(di)電(dian)(dian)壓(ya)工作條件下出(chu)現(xian)的電(dian)(dian)容(rong)(rong)(rong)(rong)器(qi)(qi)開路(lu)或(huo)容(rong)(rong)(rong)(rong)量(liang)下降超差等失(shi)(shi)效(xiao)現(xian)象(xiang).60年代以(yi)來半導體器(qi)(qi)件廣泛應用,半導體電(dian)(dian)路(lu)電(dian)(dian)壓(ya)比電(dian)(dian)子(zi)管電(dian)(dian)路(lu)低(di)得多,使電(dian)(dian)容(rong)(rong)(rong)(rong)器(qi)(qi)的實際工作電(dian)(dian)壓(ya)在某些電(dian)(dian)路(lu)中僅為幾毫伏,引起(qi)電(dian)(dian)容(rong)(rong)(rong)(rong)器(qi)(qi)低(di)電(dian)(dian)平(ping)失(shi)(shi)效(xiao),具體表現(xian)是(shi)電(dian)(dian)容(rong)(rong)(rong)(rong)器(qi)(qi)完全喪失(shi)(shi)電(dian)(dian)容(rong)(rong)(rong)(rong)量(liang)或(huo)部(bu)分喪失(shi)(shi)電(dian)(dian)容(rong)(rong)(rong)(rong)量(liang).對(dui)于低(di)電(dian)(dian)平(ping)沖擊,使電(dian)(dian)容(rong)(rong������)(rong)(rong)器(qi)(qi)的電(dian)(dian)容(rong)(rong)(rong)(rong)量(liang)恢(hui)復(fu)正常.

產生低電平失(shi)效(xiao)的原因主要(yao)在于(yu)電容(rong)器引出(chu)線與電容(rong)器極板接觸不良,接觸電阻(z����u)增大,造(zao)成電容(rong)器完全開路(lu)或電容(rong)量(liang)幅度下降.

精密(mi)聚苯(ben)乙(yi)烯薄膜電(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)一般采用鋁(lv)(lv)箔作為(wei)極(ji)(ji)(ji)板(ban)(ban),銅引出線與(yu)鋁(lv)(lv)箔極(ji)(ji)(ji)板(ban)(ban)點焊在(zai)一起.鋁(lv)(lv)箔在(zai)空氣中(zhong)(zhong)極(ji)(ji)(ji)易氧(yang)(yang)化(hua);極(ji)(ji)(ji)板(ban)(ban)表(biao)面生成(cheng)一層(ceng)(ceng)(ceng)氧(yang)(yang)化(hua)鋁(lv)(lv)半導體(ti)薄膜,在(zai)低電(dian)(dian)(dian)(dian)平條件下氧(yang)(yang)化(hua)膜層(ceng)(ceng)(ceng)上的(de)電(dian)(dian)(dian)(dian)壓不足以把(ba)它擊穿,因而(er)鋁(lv)(lv)箔間形成(cheng)的(de)間隙電(dian)(dian)(dian)(dian)容(rong)(rong)量的(de)串聯(lian)等效(xiao)(xiao)容(rong)(rong)量,間隙電(dian)(dian)(dian)(dian)容(rong)(rong)量愈(yu)(yu)小(xiao),串聯(lian)等效(xiao)(xiao)容(rong)(rong)量也愈(yu)(yu)小(xiao).因此,低電(dian)(dian)(dian)(dian)平容(rong)(rong)量取決(jue)于極(ji)(ji)(ji)板(ban)(ban)表(biao)面氧(yang)(yang)化(hua)鋁(lv)(lv)層(ceng)(ceng)(ceng)的(de)厚薄,氧(yang)(yang)化(hua)鋁(lv)(���lv)層(ceng)(ceng)(ceng)愈(yu)(yu)厚,低電(dian)(dian)(dian)(dian)平條件下電(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)的(de)電(dian)(dian)(dian)(dian)容(rong)(rong)量愈(yu)(yu)小(xiao).此外(wai),電(dian)(dian)(dian)(dian)容(rong)(rong)器(�������qi)在(zai)交流電(dian)(dian)(dian)(dian)路(lu)中(zhong)(zhong)工作時,其有(you)(you)效(xiao)(xiao)電(dian)(dian)(dian)(dian)容(rong)(rong)量會因接觸電(dian)(dian)(dian)(dian)阻過大而(er)下降,接觸電(dian)(dian)(dian)(dian)阻很(hen)大時有(you)(you)效(xiao)(xiao)電(dian)(dian)(dian)(dian)容(rong)(rong)量可減小(xiao)到(dao)開路(lu)的(de)程度.即使極(ji)(ji)(ji)板(ban)(ban)一引線間不存(cun)在(zai)導電(dian)(dian)(dian)(dian)不良的(de)間隔層(ceng)(ceng)(ceng),也會產生這種(zhong)后(hou)果.

引起精密聚(ju)苯乙烯電容器(qi)低(di)電平失(shi)效的具體因素歸納如下:

① 引(yin)線(xian)表(biao)面氧化或沾層(ceng)太薄,以致焊接不牢;

② 引線與鋁(lv)(lv)箔(bo)點焊接不良�������,沒有消除鋁(lv)(lv)箔(bo)表面(mian)點焊處的(de)氧(yang)化鋁(lv)(lv)����膜(mo)層;

③ 單引線結構的(de)焊點數過少(shao),使出現低電平失效的(de)概(gai)率增大;

④ 粗引線根(gen)部打扁部分接(jie)觸面積雖然較大,但點(dian)焊后(hou)焊點(dian)處�������(chu)應力也較大,熱處(chu)理(li)或溫(wen)循過程(cheng)中,可能(neng)損傷(shang)接(jie)觸部位,惡化接(j������ie)觸情(qing)況;

⑤ 潮氣進入電(di������an)容(rong)器芯子(zi),氧化�����腐蝕焊點(dian),使接觸電(dian)阻增大.

引起云母電容器低電平失效的具體因(yin)素(su)歸(gui)納如下:

① 銀電極和(he)引(yin)出(chu)銅��������箔之(zhi)(zhi)間(jian)(jian)以(yi)及銅箔和(he)引(yin)線卡(ka)之(zhi)(zhi)間(jian)(jian)存在一(yi)層很薄的地臘(la)薄膜(mo)(mo).低電平(ping)條件下,外加(jia)電壓不足以(yi)擊(ji)穿這層絕緣(yuan)膜(mo)(mo),產(chan)生間(jian)(jian)隙電容,并������使接觸(chu)電阻增大;

② 銀(y�����in)電(dian)極和銅箔受(shou)到有(you)害氣體侵蝕,使接觸電(dian)阻(zu)增大(da).在潮濕(����shi)的(de)硫氣環境中(zhong)銀(yin)和銅容(rong)易硫化,使極板與(yu)引線間的(de)接觸電(dian)阻(zu)上升.

(5)、金屬化紙(zhi)介(jie)電容(rong)失(shi)效(xiao)機理

??�����???? 金(jin)屬化紙介電容器的極(ji)板是真空������蒸發在電容器紙表(biao)面的金(jin)屬膜(mo)

A、電參數惡化失效

“自(zi)(zi)(zi)愈”是金(jin)屬化(hua)電(dian)(dian)容器(qi)的(de)一個獨特優點(dian),但自(zi)(zi)(zi)愈過程(cheng)頗為復雜(za),自(zi)(zi)(zi)愈雖能避免電(dian)(dian)容器(qi)立即因(yin)介(jie)質短路(lu)而擊穿,但自(zi)(zi)(zi)愈部位肯定會(hui)出現金(jin)屬微粒(li)遷移與(yu)介(jie)質材料受(shou)熱裂(lie)解的(de)現象.電(dian)(dian)容器(qi)紙(zhi)由纖維組成,纖維素是碳水化(hua)合(he)物類(�����lei)的(de)高(gao)分子(zi)物質.在高(gao)溫下電(dian)(dian)容器(qi)纖維素解成游離狀(zhuang)態的(de)碳原子(zi)或碳離子(zi),使自(zi)(zi)(zi)愈部位表面(mian)導電(dian)(dian)能力增加,導致電(dian)(dian)容器(qi)電(dian)(dian)阻下降、損(sun)耗增大與(yu)電(dian)(dian)容減小.嚴重(zhong)時可(ke)使電(dian)(dian)容器(qi)因(yin)電(dian)(dian)參數(shu)惡化(hua)程(cheng)度超過技術(shu)條(tiao)件(jian)許可(ke)范圍而失(shi)效.

金屬化紙(zhi)介電(dian)(dian)容器在低于額(e)定(ding)工作電(dian)(dian)壓的(de)條件(jian)下(xia)(xia)工作時,自(zi)愈能(neng)量不足,電(dian)(dian)容器紙(zhi)中存在的(de)導(dao)電(dian)(dian)雜質在電(di�������an)(dian)場作用于下(xia)(�������xia)形成(cheng)低阻(zu)通路,也可導(dao)致電(dian)(dian)容器絕緣電(dian)(dian)阻(zu)降低和(he)損耗增大.

������電(dian)容器紙是多孔性的(de)極性有機介(jie)質(zhi)材料,極易(yi)吸收(shou)潮氣.電(dian)容器芯(xin)子雖浸(jin)漬處理,但如果工藝不(bu)當或浸(jin)漬不(bu)純,或在電(dian)場作用(yong)下工作相(xiang)當時間(jian)后產(chan)生浸(jin)漬老化現象,則電(dian)容器的(de)絕緣電(dian)阻將(jiang)因此降低(di),損耗(hao)也將(jiang)因此增大.

電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)超差(cha)失(shi)(shi)效(xiao)(xiao)產(chan)金屬(shu)化(hua)紙(zhi)介電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)的(de)一種失(shi)(shi)效(xiao)(xiao)形式.在(zai)高溫(wen)(wen)條(tiao)件下(xia)儲(chu)存時金屬(shu)化(hua)紙(zhi)介電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)可能(neng)因(yin)電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)����增加(jia)過多而失(shi)(shi)效(xiao)(xiao),在(zai)高溫(wen)(wen)條(tiao)件下(xia)加(jia)電(dian)(dian)(dian)壓工作(zuo)時又可能(neng)因(yin)電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)減少(shao)過多而失(shi)(shi)效(xiao)(xiao).高溫(wen)(wen)儲(chu)存時半密封型(xing)金屬(shu)化(hua)紙(zhi)介電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)免不了(le)吸潮(chao),水(shui)是(shi)強極(ji)(ji)性物質(zhi),其介電(dian)(dian)(dian)常數(shu)接(jie)(jie)近浸漬(zi)電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)介電(dian)(dian)(dian)常數(shu)的(de)20倍.因(yin)此,少(shao)量(liang)(liang)(liang)(liang)潮(chao)氣侵入電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)芯子(zi),也會引(yin)(yin)起電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)顯著增大.烘烤(kao)去濕(shi)后電(dian)(dian)(dian)容(rong)(rong)(rong)呈會有所下(xia)降.如果電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)在(zai)高溫(wen)(wen)環境中(zhong)工作(zuo),則水(shui)分(fen)和(he)電(dian)(dian)(dian)場(chang)的(de)共(gong)同作(zuo)用(yong)會使金屬(shu)膜(mo)電(dian)(dian)(dian)極(ji)(��������ji)產(chan)生(sheng)電(dian)(dian)(dian)解性腐蝕,使極(ji)(ji)板有效(xiao)(xiao)面積減小與極(ji)(ji)板電(dian)(dian)(dian)阻增大,導致電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)大幅度(du)下(xia)降.如果引(yin)(yin)線與金屬(shu)膜(mo)層接(jie)(jie)觸部位產(chan)生(sheng)腐蝕,則接(jie)(jie)觸電(dian)(dian)(dian)阻增大,電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)的(de)有效(xiao)(xiao)電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)將更進一步減小.個別電(dian)(dian)(dian)容(rong)(rong)(rong)器(qi)的(de)電(dian)(dian)(dian)容(rong)(rong)(rong)量(liang)(liang)(liang)(liang)可降到接(jie)(jie)近于開路(lu)的(de)程度(du).

B、引線斷裂失效

金屬化紙介(jie)電(dian)容器在高(gao)濕環境(jing)中工(gong)作時,電(dian)容器正端(duan)引(yin)線根(gen)部會遭到嚴重(zhong)腐(fu)蝕,這(zhe)種電(dian)解(jie)性腐(fu)蝕導(dao)致引(yin)線機械強度(du)降低,嚴重(zhong)時可造(���������������zao)成引(yin)線斷(duan)裂失效.

(6)、鋁電(dian)解電(dian)容(rong)器(qi)的失效機理(li)

鋁(lv)電(dian)(dian)(dian)解(jie)電(dian)(dian)(dian)容器正極(ji)是(shi)高純(chun)鋁(lv),電(dian)(dian)(dian)介質是(shi)在金屬表面(mian)形成的(de)三氧化(hua)二鋁(lv)膜,負極(ji)是(shi)黏(nian)稠狀的(de)����電(dian)(dian)(dian)解(jie)液,工作時相當(dang)一個電(dian)(dian)(dian)解(jie)槽.鋁(lv)電(dian)(dian)(dian)�����解(jie)電(dian)(dian)(dian)容器常見失效(xiao)(xiao)模式有:漏液、爆(bao)炸、開路(lu)、擊穿、電(dian)(dian)(dian)參(can)數惡化(hua)等,有關失效(xiao)(xiao)機理分析如(ru)下.

A、漏液

鋁電(dian)(dian)(dian)(dian)(dian)解(jie)(jie)電(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)(qi)的(de)工(gong)作(zuo)電(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)泄漏(lou)(lou)是一個(ge)嚴(yan)(yan)重問題.工(gong)作(zuo)電(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)略呈現酸性,漏(lou)(lou)出的(de)工(gong)作(zuo)電(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)嚴(yan)(yan)重污染和(he)腐蝕電(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)(qi)周圍的(de)其他元器(qi)(qi)件(jian)和(he)印(yin)刷(shua)電(dian)(dian)(dian)(dian)(dian)路(lu)板.同時電(dian)(dian)(dian)(dian)(dian)解(jie)(jie)電(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)(qi)內部,由于漏(lou)(lou)液(ye)(ye)而使工(gong)作(zuo)電(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)逐漸(jian)干涸(he),喪失(shi)修補陽極氧(yang)化膜介質的(de)能(neng)力(li),導(dao)致電(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)(qi)擊穿或電(dian)(dian)(di�����an)(dian)(dian)參數惡化而失(shi)效.

產生漏(lou)(lou)液(ye)(ye)的(de)原(yuan)因很多,主要(yao)是鋁電解(jie)電容(rong)器密(mi)(mi)封(feng)(feng)不(bu����)佳.采用鋁負極箔(bo)夾在外殼邊與(yu)封(feng)(feng)口板之(zhi)間的(de)封(feng)(feng)口結構時(shi)很容(rong)易在殼邊滲漏(lou)(lou)電解(jie)液(ye)(ye).采用橡膠塞密(mi)(mi)封(feng)(feng)的(de)電容(rong)器,也(ye)(ye)可能(neng)因橡膠老化、龜裂而(er)引起漏(lou)(lou)液(ye)(ye).此外,機(ji)械密(mi)(mi)封(feng)(feng)工藝(yi)有(you)問題的(de)產品也(ye)(ye)容(rong)易漏(lou)(lou)液(ye)(ye).總之(zhi),漏(lou)(lou)液(ye)(ye)與(yu)密(mi)(mi)封(feng)(feng)結構、密(mi)(mi)封(feng)(feng)材料與(yu)密(mi)(mi)封(feng)(feng)工藝(yi)有(you)密(mi)(mi)切的(de)關系.

B、爆炸

鋁電解電容(rong)器在(zai)工(gong)(gong)作電壓(ya)(ya)中交(jiao)流(liu)(liu)成分(fen)(fen)過大(da)(da)(da)(da),或氧(yang)化膜(mo)(mo)介質有較(jiao)多缺陷(xian),或存在(zai)氯根(gen)、硫(liu)酸根(gen)之類(lei)有害(hai)的(de)(de)(de)陰離(li)子,以致漏電流(liu)(liu)較(jiao)大(da)(da)(da)(da)時(shi)電解作用產(chan)(chan)生氣(qi)(qi)體的(de)(de)(de)速率較(jiao)快,大(da)(da)(da)(da)部分(fen)(fen)氣(qi)(qi)體用于修補陽極氧(yang)化膜(mo)(mo),少(shao)部分(fen)(fen)氧(yang)氣(qi)(qi����)儲存在(zai)電容(rong)器殼(ke)內(nei).工(gong)(gong)作時(shi)間(jian)愈(yu)(yu)(yu)長,漏電流(liu)(liu)愈(yu)(yu)(yu)大(da)(da)(da)(da),殼(ke)內(nei)氣(qi)(qi)體愈(yu)(yu)(yu)多,溫度(du)愈(yu)(yu)(yu)高.電容(rong)器金屬殼(ke)內(nei)外(wai)的(de)(de)(de)氣(qi)(qi)壓(ya)(ya)差值將隨工(gong)(gong)作電壓(ya)(ya)和工(gong)(gong)作時(shi)間(jian)的(de)(de)(de)增(zeng)加而增(zeng)大(da)(da)(da)(da).如果(guo)(guo)產(chan)(chan)品密封(feng)不佳,則將造成漏液;如果(guo)(guo)密封(feng)良好,又(you)沒(mei)有任(ren)何防爆(bao)(bao)措施,則氣(qi)(qi)壓(ya)(ya)增(zeng)大(da)(da)(da)(da)到一定程度(du)就會(hui)引(yin)起電容(rong)器爆(bao)(bao)炸.高壓(ya)(ya)大(da)(da)(da)(da)容(rong)量電容(rong)器的(de)(de)(de)漏電流(liu)(liu)較(jiao)大(da)(da)(da)(da),爆(bao)(bao)炸可(ke)能性更大(da)(da)(da)(da).目前,已普遍采用防爆(bao)(bao)外(wai)殼(ke)結(jie)構,在(zai)金屬外(wai)殼(ke)上部增(zeng)加一道褶縫(feng),氣(qi)(qi)壓(ya)(ya)高時(shi)將褶縫(feng)頂開(kai),增(zeng)大(da)(da)(da)(da)殼(ke)內(nei)容(rong)積,從(cong)而降低氣(qi)(q�������i)壓(ya)(ya),減(jian)少(shao)爆(bao)(bao)炸危險.

C、開路

鋁電(dian)解電(dian)容器(qi)在高(gao)溫或潮熱環境(jing)中長期(qi)工作時可能(neng)出現開路失效,其原因(yin)在于(yu)(yu)陽(yang)極引(yin)出箔(bo)(bo)片遭(zao)受電(dian)化學腐(fu)蝕(shi)而斷������裂.對于(yu)(yu)高(gao)壓大容量電(dian)容器(qi),這種失效模式較多.此(ci)外,陽(yang)極引(yin)出箔(bo)(bo)片和陽(yang)極箔(bo)(bo)鉚接后,未經充(chong)分平(ping),則(ze)接觸不良會使電(dian)容器(qi)出現間(jian)歇開路.

鋁電解(jie)電容器內采用以DMF(二(er)甲基(ji)酰胺)為溶(rong)劑(ji)的(de)工(gong)作電解(jie)液時,DMF溶(rong)液是氧(yang)化(hua)(hua)劑(ji),在高溫下氧(yang)化(hua)(hua)能(neng)力(li)更強.工(gong)作一段時間(jian)后可能(neng)因陽極引出(chu)箔(bo)片(pian)與(yu)(yu)焊(han)片(pian)的(de)鉚接部位生成氧(yang)化(hua)(hua)膜而引起電容器開路�����.如果采用超聲波焊(han)接機把(ba)引出(chu)箔(bo)片(pian)與(yu)(yu)焊(han)點在一起,可������則減少這類失(shi)效現象.

D、擊穿

鋁(lv)電(dian)(dian)解電(dian)(dian)容器擊穿(chuan)(chuan)是由于陽極(ji)氧(yang)化(hua)鋁(lv)介質膜(mo)破裂,導致(zhi)電(dian)(dian)解液直接(jie)與陽極(ji)接(jie)觸而造成的(de)(de).氧(yang)化(hua)鋁(lv)膜(mo)可(ke)能因(yin)各種材料,工(gong)藝或(huo)環境(jing)條件方面的(de)(de)原因(yin)而受到(dao)局部(bu)損(sun)(sun)傷(shang).在外加(jia)電(dian)(dian)場的(de)(de)作用下(xia)工(gong)作電(dian)(dian)解液提供的(de)(de)氧(yang)離子可(ke)在損(sun����)(sun)傷(shang)部(bu)位重新形(xing)成氧(yang)化(hua)膜(mo),使(shi)陽極(ji)氧(yang)化(hua)膜(mo)得以(yi)填平修復(fu).但是如果(guo)在損(sun)(sun)傷(shang)部(bu)位存在雜質離子或(huo)其他缺陷,使(shi)填平修復(fu)工(gong)作無法完善,則在陽極(ji)氧(yang)化(hua)膜(mo)上(shang)會留下(xia)微孔(kong),甚至可(ke)能成為穿(chuan)(chuan)透(tou)孔(kong),使(shi)鋁(lv)電(dian)(dian)解電(dian)(dian)容器擊穿(chuan)(chuan).

此外,隨(sui)著使(shi)用����(yong)(yong)和(he)儲存時(shi)(shi)間(jian)的(de)增長,電解(jie)液(ye)(ye)中(zhong)(zhong)溶劑(ji)逐漸消耗和(he)揮發,使(shi)溶液(ye)(ye)酸值上(shang)升,在(zai)儲存過程(cheng)中(zhong)(zhong)對氧(yang)化(hua)(hua)膜(mo)(mo)層發生(sheng)腐(fu)蝕作用(yong)(yong).同時(shi)(shi),由于電解(jie)液(ye)(ye)老化(hua)(hua)與干涸,在(zai)電場作用(yong)(yong)下(xia)已無法提(ti)供(gong)氧(yang)離子修(xiu)補氧(yang)化(hua)(hua)膜(mo)(mo),從而(er)喪(sang)失了自愈作用(yong)(yong),氧(yang)化(hua)(hua)膜(mo)(mo)一經損壞就會導致(zhi)電容(rong)(rong)器擊(ji)(ji)穿.工(gong)藝(yi)缺(que)陷也(ye)是鋁電解(jie)電容(rong)(rong)器擊(ji)(ji)穿的(de)一個主要原因.如果(guo)賦能過程(cheng)中(zhong)(zhong)形成的(de)陽(yang)極氧(yang)化(hua)(hua)膜(mo)(mo)不夠致(zhi)密與牢固,在(zai)后續的(de)裁(cai)片、鉚接工(gong)藝(yi)中(zhong)(zhong)又(you)使(shi)氧(yang)化(hua)(hua)膜(mo)(mo)受到嚴重損傷(shang).這種陽(yang)極氧(yang)化(hua)(hua)膜(mo)(mo)難(nan)以(yi)在(zai)最后的(de)老煉工(gong)序中(zhong)(zhong)修(xiu)補完善,以(yi)致(zhi)電容(rong)(rong)器使(shi)用(yong)(yong)過程(cheng)中(zhong)(zhong),漏電流很(hen)大(da),局部(bu)自愈已挽救不了最終擊(ji)(ji)穿的(de)命運(yun).又(you)如鉚接工(gong)藝(yi)不佳時(shi)(shi),引出箔條上(shang)的(de)毛剌(la)嚴重剌(la)傷(shang)氧(yang)化(hua)(hua)膜(mo)(mo),刺(ci)傷(shang)部(bu)位(wei)漏電流很(hen)大(da),局部(bu)過熱使(shi)電容(rong)(rong)器產生(sheng)熱擊(ji)(ji)穿.

E、電參數惡化

A、電容(rong)量下降與損耗增(zeng)大

鋁電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)電(dian)(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)的電(dian)(dian)(dian)(dian)(dian)(dian)容(rong)量在工(gong)作(zuo)早(zao)期(qi)緩(huan)慢下(xia)(xia)降(jiang),這是由于(yu)負(fu)荷過程中工(gong)作(zuo)電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)不(bu)斷修補并增(zeng)厚陽極氧(yang)化(hua)膜所致(zhi)(zhi).鋁電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)電(dian)(dian)(dian)(dia�����n)(dian)(dian)容(rong)器(qi)在使(shi)(shi)用后(hou)期(qi),由于(yu)電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)耗損(sun)較多(duo)、溶(rong)液(ye)(ye)變稠,電(dian)(dian)(dian)(dian)(dian)(dian)阻率因黏(nian)度增(zeng)大(da)而上(shang)(shang)升(sheng),使(shi)(shi)工(gong)作(zuo)電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)質的等效串(chuan)聯電(dian)(dian)(dian)(dian)(dian)(dian)阻增(zeng)大(da),導致(zhi)(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)損(sun)耗明顯增(zeng)大(da).同(tong)時(shi),黏(nian)度增(zeng)大(da)的電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)液(ye)(ye)難于(yu)充分接觸經腐(fu)蝕處理的凹(ao)凸不(bu)平鋁箔表面上(shang)(shang)的氧(yang)化(hua)膜層,這樣就使(shi)(shi)鋁電(dian)(dian)(dian)(dian)(dian)(dian)解(jie)(jie)電(dian)(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)的極板有(you)效面積減小,引起電(dian)(dian)(dian)(dian)(dian)(dian)容(rong)量急(ji)劇(ju)下(xia)(xia)降(jiang).這也是電(dian)(dian)(dian)(dian)(dian)(dian)容(rong)器(qi)使(shi)(shi)用壽命臨(lin)近結(jie)束的表現(xian).

此������外,如果(guo)工(gong)(gong)作電(dian)解液在低(di)溫(wen)(wen)下黏度增大(da)過(guo)多,也會造成損(sun)耗增大(da)與電(dian)容量(liang)急(ji)劇下降的(de)后果(guo).硼(peng)酸一乙二醇系統(tong)工(gong)(gong)作電(dian)解液的(de)低(di)溫(wen)(wen)性能不(bu)佳,黏度過(guo)大(da)導致等效串聯(lian)電(dian)阻激增,使損(sun)耗變大(da)和有(you)效電(dian)容量(liang)驟減,從而引��������(yin)起鋁(lv)電(dian)解電(dian)容器在嚴寒環(huan)境中(zhong)使用時失效.

B、漏電流增加

漏(lou)電(dian)流(liu)增(zeng)加往往導致(zhi)鋁(lv)電(dian)解電(dian)容器(qi)失(shi)效(xiao)(xiao).賦能工(gong)藝(yi)水平低,所形成的(de)氧(yang)化(hua)(hua)膜(mo)不(bu)夠致(zhi)密與牢固,開片工(gong)藝(yi)落后,氧(yang)化(hua)(hua)膜(mo)損傷與沾污嚴重,工(gong)作電(dian)解液配方(fang)不(bu)佳(jia),原材料純度不(bu)高,電(dian)解液的(de)化(hua)(hua)學(xue)性質(zhi)(zhi)(zhi)與電(������dian)化(hua)(hua)學(xue)性質(zhi)(zhi)(zhi)難以長期穩定(ding),鋁(lv)箔純度不(bu)高,雜質(zhi)(zhi)(zhi)含量多……這些因素均可能造(zao)成漏(lou)電(dian)流(liu)超差失(shi)效(xiao)(xiao).

鋁電(dian)(dian)解電(dian)(dian)容(rong)器(qi)(qi)中氯離子沾(zhan)污(wu)嚴重,漏電(dian)(dian)流(liu)導致(zhi)沾(zhan)污(wu)部位氧化(hua)膜分(fen)解,造成穿孔,促使(shi)電(dian)(dian)流(liu)進(jin)一(yi)步(bu)增大(da).此(ci)外(wai)������,鋁箔(bo)的雜(za)質(zhi)含量較高,一(yi)般鐵雜(za)質(zhi)顆粒(li)的尺寸大(da)于(yu)(yu)陽(yang)極氧化(hua)膜的厚度,使(shi)電(dian)(dian)流(liu)易于(yu)(yu)傳導.銅(tong)與硅雜(za)質(zhi)的存(cun)在影(ying)響鋁氧化(hua)物向(xiang)晶態結構轉(zhuan)變.銅(tong)和鋁還可在電(dian)(dian)解質(zhi)內組成微電(dian)(dian)池,使(shi)鋁箔(bo)�������遭到(dao)腐蝕(shi)破壞.總之,鋁箔(bo)中金屬雜(za)質(zhi)的存(cun)在,會使(shi)鋁電(dian)(dian)解電(dian)(dian)容(rong)器(qi)(qi)漏電(dian)(dian)流(liu)增大(da),從而縮短電(dian)(dian)容(rong)器(qi)(qi)的壽(shou)命.

3、提高電容器可靠性的措施

對(dui)材料、結(jie)構和制造(zao)工藝進(jin)行改(gai)進(jin)說明.

1、電極材料的改進

陶(tao)瓷電������(dian)(dian)容器一直(zhi)使用(yong)銀(yin)電(dian)(dian)極.銀(yin)離(li)子遷移和由(you)(you)此而(er)引起含鈦(tai)陶(tao)瓷介質的加速老化是導(dao)致陶(tao)瓷電(dian)(dian)容器失效的主要原因.有的廠家生產(chan)陶(tao)瓷電(dian)(dian)容器已不用(yong)銀(yin)電(di�����an)(dian)極,而(er)改用(yong)鎳(nie)(nie)電(dian)(dian)極,在陶(tao)瓷基片(pian)上采用(yong)化學鍍鎳(nie)(nie)工藝.由(you)(you)于(yu)鎳(nie)(nie)的化學穩定性比銀(yin)好,電(dian)(dian)遷移率低,提高(gao)了陶(tao)瓷電(dian)(dian)容器的性能和可靠性.

國(guo)產云母(mu)電(dian)(dian)容器的電(dian)(dian)極(ji)材(cai)料(liao)也是銀,同樣存在銀離子(zi)遷移現象(xiang).日本海纜通信(������xin)系統中用的云母(mu)器,它的電(dian)(dian)極(�������ji)材(cai)料(liao)及電(dian)(dian)極(ji)引線(xian)間(jian)的連接(jie)均采用金,這(zhe)就保證了(le)云母(mu)電(dian)(dian)容器優良的性能和(he)高(gao)可靠性.

鍍金云母電(dian)容(rong)器(qi)(qi)與鍍銀云母電(dian)容(rong)器(qi)(qi)相(xiang)(xiang)比較:電(dian)容(rong)溫(wen)度系(xi)數(shu)(shu),前者(zhe)(zhe)約為后(hou)者(zhe)(zhe)的(de)1/2,且偏差也小;濕度對容(rong)量(l���iang)的(de)影響,前者(zhe)(zhe)比后(hou)者(zhe)(zhe)小一個數(shu)(shu)量(liang)級,且是(shi)可逆(ni)的(de);損耗角正切(qie)值(zhi),前者(zhe)(zhe)比后(hou)者(zhe)(zhe)小個數(shu)(shu)量(liang)級;在(zai)電(dian)壓負荷(he)下電(dian)容(rong)量(liang)相(xiang)(xiang)對變化率(lv),前者(zhe)(zhe)約為后(hou)者(zhe)(zhe)的(de)1/5~1/10.據推算,鍍金云母電(dian)容(rong)器(qi)(qi)工作20年的(de)電(dian)容(rong)量(liang)變化率(lv)≤±0.1%.

改(gai)進電(dian)(dian)(dian)(dian)(dian)極(ji)(ji)材料的(de)另(ling)(ling)一個例子是金(jin)屬(shu)(shu)化(hua)(hua)紙(zhi)介(jie)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi).金(jin)屬(shu)(shu)化(hua)(hua)紙(zhi)介(jie)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)都采用(yong)鋅(xin)(xin)(xin)蒸發在(zai)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)紙(zhi)上形成(cheng)(cheng)的(de)金(jin)屬(shu)(shu)層(ceng)作為電(dian)(dian)(dian)(dian)(dian)極(ji)(ji).鋅(xin)(xin)(xin)膜在(zai)空氣(qi)中(zhong)(zhong)(zhong)易氧(yang)(yang)化(hua)(hua),生(sheng)成(cheng)(cheng)半導體(ti)性(xing)質的(de)氧(yang)(yang)化(hua)(hua)鋅(xin)(xin)(xin),而且(qie)會繼續(xu)向底層(ceng)氧(yang)(yang)化(hua)(hua),造(zao)成(cheng)(cheng)板(ban)極(ji)(ji)電(dian)(dian)(dian)(dian)(dian)阻(zu)的(de)增加(jia)和電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)損耗(hao)(hao)的(de)增大(da).此外,鋅(xin)(xin)(xin)金(jin)屬(shu)(shu)化(hua)(hua)膜在(zai)潮濕環(huan)境(jing)下(xia)易腐蝕(shi).鋅(xin)(xin)(xin)金(jin)屬(shu)(shu)化(hua)(hua)膜的(de)另(ling)(ling)一個缺點是自(zi)愈(yu)所需要(yao)的(de)能(neng)量(liang)較(jiao)大(da),而且(qie)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)經(jing)擊穿自(zi)愈(yu)后其絕(jue)(jue)緣(yuan)電(dian)(dian)(dian)(dian)(dian)阻(zu)值較(jiao)低(di).為了(le)提高金(jin)屬(shu)(shu)化(hua)(hua)紙(zhi)介(jie)電(dian)(dian)(dian)(dian)��������(dian)容(rong)(rong)器(qi)(qi)的(de)性(xing)能(neng)和可靠性(xing),已用(yong)鋁(lv)(lv)(lv)金(jin)屬(shu)(shu)化(hua)(hua)層(ceng)來代替鋅(xin)(xin)(xin)金(jin)屬(shu)(shu)化(hua)(hua)層(ceng).大(da)氣(qi)中(zhong)(zhong)(zhong)在(zai)鋁(lv)(lv)(lv)膜的(de)表面(mian)會生(sheng)成(cheng)(cheng)一層(ceng)薄而堅固的(de)氧(yang)(yang)化(hua)(hua)氯膜.使(shi)鋁(lv)(lv)(lv)膜不再繼續(xu)氧(yang)(yang)化(hua)(hua).同時氧(yang)(yang)化(hua)(hua)氯膜對潮氣(qi)抗腐蝕(shi)性(xing)能(neng)好.另(ling)(ling)外鋁(lv)(lv)(lv)金(jin)屬(shu)(shu)化(hua)(hua)層(ceng)自(zi)愈(yu)性(xing)能(neng)好,鋁(lv)(lv)(lv)電(dian)(dian)(dian)(dian)(dian)極(ji)(ji)可以(yi)在(zai)介(jie)質上殘(can)存(cun)的(de)微量(liang)潮氣(qi)和低(di)電(dian)(dian)(dian)(dian)(dian)壓(ya)作用(yong)下(xia)產生(sheng)電(dian)(dian)(dian)(dian)(dian)化(hua)(hua)學反(fan)應,生(sheng)成(cheng)(cheng)氧(yang)(yang)化(hua)���(hua)鋁(lv)(lv)(lv)介(jie)質膜,經(jing)過一段(duan)時間,電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)的(de)絕(jue)(jue)緣(yuan)電(dian)(dian)(dian)(dian)(dian)阻(zu)得到(dao)恢復.此外,鋁(lv)(lv)(lv)的(de)比電(dian)(dian)(dian)(dian)(dian)導較(jiao)鋅(xin)(xin)(xin)大(da),這就(jiu)減小(xiao)了(le)板(ban)極(ji)(ji)電(dian)(dian)(dian)(dian)(dian)阻(zu)和電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)的(de)損耗(hao)(hao).因(yin)此,鋁(lv)(lv)(lv)在(zai)金(jin)屬(shu)(shu)化(hua)(hua)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)的(de)生(sheng)產中(zhong)(zhong)(zhong)取代鋅(xin)(xin)(xin)做電(dian)(dian)(dian)(dian)(dian)極(ji)(ji)改(gai)善了(le)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)的(de)性(xing)能(neng),提高了(le)電(dian)(dian)(dian)(dian)(dian)容(rong)(rong)器(qi)(qi)的(de)可靠性(xing).

2、工作電解質的改進

鋁電(dian)(dian)解電(dian)(dian)容(rong)器工作(zuo)電(dian)(dian)解質為硼(peng)酸一乙(yi)醇(chun)系統,其工作(zuo)溫度范(fan)圍(wei)為+85~—40℃.在低(di)溫下,由于乙(yi)二醇(chun)中的(de)羥基彼(bi)此以(yi)氫������鍵聯合(he),出現(xian)聚合(he)物,以(yi)致工作(zuo)電(dian)(dian)解液(ye)變(bian)稠凍結(jie),電(dian)(dian)阻率(lv)急劇增大(da)(da),電(dian)(dian)容(rong)量下降和損耗角(jiao)正切值增大(da)(da),使(shi)電(dian)(dian)容(rong)器的(de)性能(neng)惡化(hua).近來普遍采用(yong)的(de)以(yi)DMF為溶劑的(de)工作(zuo)電(dian)(dian)解液(ye),在較寬(kuan)的(de)溫度范(fan)圍(wei)內(-�����55~+85℃)電(dian)(dian)性能(neng)優良.

為(wei)了解(jie)決液體鉭(tan)電(dian)(dian)解(jie)電(dia�����n)(dian)容器(qi)漏液問(wen)題,除了在密封結(jie)構上采取措施(shi)外(wai),采用凝(ning)(ni�������ng)膠狀電(dian)(dian)解(jie)質,因為(wei)凝(ning)(ning)膠狀電(dian)(dian)解(jie)質黏度大,不容易從(cong)微小的(de)縫隙(xi)中漏出.

3、電介質材料的改進

電(dian)(dian)介(jie)(jie)質材料是決定(ding)電(dian)(dian)容(rong)器(qi)(qi)性(xing)(xing)能(neng)和(he)可(ke)靠性(xing)(xing)的(de)關鍵材料.以往生產(chan)的(de)聚(ju)苯(ben)乙烯(xi)電(dian)(dian)容(rong)器(qi)(qi),其電(dian)(dian)介(jie)(jie)質是采用厚度為(wei)20μm的(de)聚(ju)苯(ben)乙烯(xi)單層薄膜(mo)(mo)(mo),由于薄膜(mo)(mo)(mo)的(de)厚度不均、有針孔、有導電(dian)(dian)雜質和(he)微粒先進(jin)原(yuan)因,制成(cheng)的(de)電(dian)(dian)容(rong)器(qi)(qi)就(jiu)(jiu)(jiu)存在(zai)著某些陷患,在(zai)外(wai)部各種環境和(he)電(dian)(dian)應力作用下(xia),這(zhe)些缺陷就(jiu)(jiu)(jiu)會逐(zhu)漸暴露(lu)出來(lai),導致電(dian)(dian)容(rong)器(qi)(qi)的(�����de)擊穿、開路(lu)或電(dian)(dian)參(can)數(shu)超差失效.為(wei)了提高(gao)和(he)產(chan)品的(de)性(xing)(xing)能(neng)和(he)可(ke)靠性(xing)(xing).電(dian)(dian)容(rong)器(qi)(qi)的(de)電(dian)(dian)介(jie)(jie)質由原(yuan)來(lai)單層20μm厚薄膜(mo)(mo)(mo)改進(jin)為(wei)雙(shuang)層10μm薄膜(mo)(mo)(mo)這(zhe)樣電(dian)(dian)介(jie)(jie)質的(de)厚度仍為(wei)20μm,電(dian)(dian)容(rong)器(qi)(qi)的(de)體積不變(bian),但產(chan)品的(de)質量(liang)卻(que)提高(gao)了.因為(wei)雙(shuang)層薄膜(mo)(mo)(mo)可(ke)以互相掩蓋(gai)薄膜(mo)(mo)(mo)中(zhong)的(de)缺陷和(he)疵點(dian),這(zhe)就(jiu)(jiu)(jiu)使得電(dian)(dian)容(rong)器(qi)(qi)的(de)耐壓和(he)可(ke)靠性(xing)(xing)得到(dao)了提高(gao).

又如,以銀(yin)做電(dian)極(ji)(ji)的(de)(de)(de)(de)(de)獨石低頻瓷(ci)(ci)(ci)介(jie)電(dian)容(rong)器,由(you)于銀(yin)電(dian)極(ji)(ji)和瓷(ci)(ci)(ci)料(liao)在(zai)900℃下一次燒成時(shi)瓷(ci)(ci)(ci)料(liao)欠燒不(bu)能(neng)獲得致密的(de)(de)(de)(de)(de)陶(tao)瓷(ci)(ci)(ci)介(jie)質,存(cun)在(zai)較(jiao)大(da)(da)的(de)(de)(de)(de)(de)氣孔率;此(ci)外(wai)銀(yin)電(dian)極(ji)(ji)常用的(de)(de)(de)(de)(de)助熔(rong)劑氧化(hua)(hua)(hua)鋇(bei)會滲透(tou)到(dao)瓷(ci)(ci)(ci)體(ti)內部(bu),在(zai)高溫下依靠(kao)氧化(hua)(hua)(hua)鋇(bei)和銀(yin)之間良好的(de)(de)(de)(de)(de)浸潤“互熔(rong)”能(neng)力(li),使(shi)電(dian)極(ji)(ji)及介(jie)質內部(bu)出���������(chu)現熱(re)擴散現象,即宏觀上看到(dao)的(de)(de)(de)(de)(de)“瓷(ci)(ci)(ci)吸銀(yin)”現象.銀(yin)伴隨著氧化(hua)(hua)(hua)鋇(bei)進入瓷(ci)(ci)(ci)體(ti)中去后,大(da)(da)大(da)(da)減薄了(le)介(jie)質的(de)(de)(de)(de)(de)有(you)效厚度,引起產品(pin)絕緣(yuan)電(dian)阻(�����zu)的(de)(de)(de)(de)(de)減少和可(ke)靠(kao)性(xing)(xing)(xing)的(de)(de)(de)(de)(de)降低.為了(le)提(ti)高獨石電(dian)容(rong)器的(de)(de)(de)(de)(de)可(ke)靠(kao)性(xing)(xing)(xing),改(gai)用了(le)銀(yin)—鈀電(dian)極(ji)(ji)代替通常含有(you)的(de)(de)(de)(de)(de)氧化(hua)(hua)(hua)鋇(bei)電(dian)極(ji)(ji),并且在(zai)資料(liao)配方(fang)中添加了(le)1%的(de)(de)(de)(de)(de)5#玻(bo)璃粉.消除了(le)在(zai)高溫下一次燒結時(shi)金屬電(dian)極(ji)(ji)向(xiang)瓷(ci)(ci)(ci)介(jie)質層(ceng)的(de)(de)(de)(de)(de)熱(re)擴散現象,能(neng)促使(shi)瓷(ci)(ci)(ci)料(liao)燒結致密化(hua)(hua)(hua).使(shi)得產品(pin)的(de)(de)(de)(de)(de)性(xing)(xing)(xing)能(neng)和可(ke)靠(kao)性(xing)(xing)(xing)有(you)較(jiao)大(da)(da)提(ti)高,與原工(gong)藝(yi)和介(jie)質材料(liao)相(xiang)比較(jiao),電(dian)容(rong)器的(de)(de)(de)(de)(de)可(ke)靠(kao)性(xing)(xing)(xing)提(ti)高了(le)1~2個數(shu)量級.

4、結構的改進

上面已論述了聚苯乙烯電(dian)容(rong)器(qi)的(de)(de)低電(dian)平(ping)失效(xiao).導(dao)致低電(dian)平(ping)不(bu)(bu)(bu)時通時不(bu)(bu)(bu)通的(de)(de)原因是(shi)其引(yin)線(xian)(xian)和板(ban)有(you)焊(han)接不(bu)(bu)(bu)好而(er)引(yin)起的(de)(de).原來的(de)(de)引(yin)線(xian)(xian)結(jie)構(gou)是(shi)用(yong)較(jiao)粗的(de)(de)單引(yin)線(xian)(xian),與(yu)鋁箔厚度比(bi)較(jiao)尺寸(cun)相差懸殊,因此點(dian)焊(han)質(zhi)������(zhi)量(liang)不(bu)(bu)(bu)高.后改(gai)用(yong)細引(yin)線(xian)(xian),并(bing)將沖壓加(jia)工改(gai)進為輾軋加(jia)工.這樣即可減少(shao)加(jia)式過(g������uo)程中產生(sheng)毛刺,點(dian)焊(han)質(zhi)(zhi)量(liang)也高.此外(wai),經(jing)過(guo)分析研究,從單引(yin)線(xian)(xian)結(jie)構(gou)較(jiao)細的(de)(de)Φ0.2mm打扁引(yin)線(xian)(xian),在(zai)卷芯(xin)的(de)(de)芯(xin)軸孔(kong)中間位(wei)置插入Φ0.8mm的(de)(de)絕緣(yuan)線(xian)(xian),兩端插入預先打有(you)凹槽的(de)(de)Φ0.8mm浸錫(xi)引(yin)線(xian)(xian)作為加(jia)固引(yin)線(xian)(xian),經(jing)熱(re)處理聚合(he)固定.用(yong)雙引(yin)線(xian)(xian)結(jie)構(gou)后,聚苯乙烯電(dian)容(rong)器(qi)低電(dian)平(ping)失效(xiao)的(de)(de)概率由(you)萬分之五減少(shao)到四百(bai)萬分之一.

細雙引線(xian)加(jia)固(gu)(gu)引線(xian)結構的(de)(de)(de)電(dian)(dian)容(rong)器(qi)(qi),由于附加(jia)了(le)(le)較(jiao)粗的(de)(de)(de)Φ0.8mm外部連接加(jia)固(gu)(gu)引線(xian),并(bing)且(qie)在插入芯子(zi)內的(de)(de)(de)一端(duan)上有一個(ge)凹槽,保(bao)證了(le)(le)引線(xian)的(de)(de)(de)穩(wen)固(gu)(gu)性,所(suo)以提高了(le)(le)電(dian)(dian)容(rong)器(qi)(qi)外部連接的(de)(de)(de)強(qiang)度(du),能(neng)耐振,不易折斷(duan).同(tong)時,在兩根加(jia)固(gu)(gu)引線(xian)間有一段相同(tong)直徑的(de)(de)(de)絕緣線(xian),這不僅可(ke)以防止兩極間可(ke)能(neng)發生的(de)(de)(de)偶然擊(ji)穿,而且(qie)還能(neng)使電(dian)(dian)容(rong)器(qi)(qi)聚合后變形(xing)小,使芯子(zi)內介(jie)質薄膜的(de)(de)(de)應力(li)均勻(yun),這就改善了(le)(le)電(dian)(dian)容(r�����ong)量的(de)(de)(de)穩(wen)定性.

長期以來,鋁電(dian)(dian)解(jie)電(dian)(dian)容(rong)器(qi)的(de)爆(bao)炸是令人生畏的(de),CV乘積(ji)大的(de)電(dian)(dian)容(rong)器(qi)爆(bao)炸的(de)可(ke)能(neng)性(xing)更大,而且破壞性(xing)也大.為了提高鋁電(dian)(dian)解(jie)電(dian)(dian)容(rong)器(qi)的(de)可(ke)靠性(xing),提高整機的(de)可(ke)靠性(xing)和安全性(xing),國內已(yi)經度(du)制(zhi)了有防(fang)(fang)爆(bao)結構(gou)的(de)鋁電(dian)(dian)解(jie)電(dian)(dian)容(rong)器(qi).當電(dian)(dian)容(rong)器(qi)內部氣壓加到一(yi)定程(cheng)度(du)時,防(fang)(fang)爆(�������bao)閥釋放氣體而防(fang)(fang)止爆(bao)炸.

5、工藝方面的改進

為了(le)提(ti)高鋁電(dian)(dian)(dian)解電(dian)(dian)(dian)容器的(de)(de)性(xing)(xing)(xing)能和壽(shou)命,就必須獲得(de)(de)性(xing)(xing)(xing)能優良(liang)、結構致(zhi)密、缺陷少(shao)和耐酸(suan)(suan)堿腐(fu)(fu)蝕的(de)(de)電(dian)(dian)(dian)介(jie)質(zhi)氧(yang)(yang)化(hua)(hua)氯薄膜(mo).傳統的(de)(de)鋁電(dian)(dian)(dian)解電(dian)(dian)(dian)容器賦能工(gong)藝(yi)是(shi)采(cai)用硼酸(suan)(suan)一(yi)乙(yi)二醇系統賦能液,雖然賦能后獲得(de)(de)的(de)(de)氧(yang)(yang)化(hua)(hua)膜(mo)介(jie)電(dian)(dian)(dian)性(xing)(xing)(xing)能良(liang)好,但其氧(yang)(yang)化(hua)(hua)膜(mo)抗水合能力和耐酸(suan)(suan)堿腐(fu)(fu)蝕性(xing)(xing)(xing)能較差(cha),因而鋁電(dian)(dian)(dian)解電(dian)(dian)(dian)容器的(de)(de)性(xing)(xing)(xing)能和可靠性(xing)�����(xing)(xing)都差(cha).采(cai)用已(yi)二酸(suan)(suan)形成工(gong)藝(yi),由于已(yi)二酸(suan)(suan)在電(dian)(dian)(dian)解液中是(shi)水的(de)(de)表面活性(xing)(xing)(xing)物質(zhi),其羰基具有(you)較強的(de)(de)電(dian)(dian)(dian)負性(xing)(xing)(xing),極易吸附到(dao)陽(yang)極箔上,阻止陽(yang)極氧(y�����ang)(yang)化(hua)(hua)時(shi)的(de)(de)晶胞生長(chang),迫使(shi)放電(dian)(dian)(dian)離子產生新的(de)(de)晶核,生成致(zhi)密的(de)(de)氧(yang)(yang)化(hua)(hua)膜(mo).氧(yang)(yang)化(hua)(hua)膜(mo)的(de)(de)疵點、空洞(dong)、裂紋和縫(feng)隙都較少(shao),無論是(shi)在常溫還是(shi)在高溫條件(jian)下,產品(pin)的(de)(de)漏電(dian)(dian)(dian)流都比較小,延(yan)長(chang)了(le)產品(pin)的(de)(de)平均壽(shou)命,提(ti)高了(le)可靠性(xing)(xing)(xing).

為(wei)了解決(jue)云母電容器低(di)電平(ping)失效(xiao)(xiao),即解決(jue)引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)線(xian)(xian)和(he)電極接(jie)觸(chu)不良(liang)問題,將原來(lai)(lai)用(yong)銅箔(bo)接(jie)觸(chu)的引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)線(xian)(xian)改(gai)(gai)為(wei)焊(han)(han)(han)接(jie)工藝引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu),能基本(ben)消(xiao)除低(di)電平(ping)不通的失效(xiao)(xiao)模式.電極和(he)引(yin)(yin)(yin)(yin)線(xian)(xian)之間(jian)(jian)的焊(han)(han)(han)接(jie)方(fang)法有(you)兩種:全焊(han)(han)(han)接(jie)法和(he)點焊(han)(han)(han)法.全焊(han)(han)(han)接(jie)法是指云母片上(shang)銀(yin)電極和(he)引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)線(xian)(xian)之間(jian)(jian),引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)線(xian)(xian)和(he)引(yin)(yin)(yin)(yin)線(xian)(xian)卡子(zi)(zi)之間(jian)(jian)全部、焊(han)(han)(han)接(jie)起來(lai)(lai).方(fang)法是把引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)線(xian)(xian)銅箔(bo)改(gai)(gai)為(wei)熱浸銅箔(bo),芯(xin)組裝配(pei)方(fang)法和(he)原來(lai)(lai)一樣.芯(xin)組打(da)好(hao)卡子(zi)(zi)之后,通過施加溫(wen)度(du)和(he)壓(ya)力,一道工序把電極銀(yin)層和(he)引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)線(xian)(xian)之間(jian)(jian)、引(yin)(yin)(yin)(yin)出(c�������hu)(chu)(chu)(chu)線(xian)(xian)和(he)引(yin)(yin)(yin)(yin)出(chu)(chu)(chu)(chu)卡子(zi)(zi)之間(jian)(jian),全部焊(han)(han)(han)接(jie)起來(lai)(lai).

美國(guo)生(sheng)產高可(ke)靠云母電容器(qi)采用點(dian)焊(han)法.即云母片(pian)上(shang)電極和引出線連接采用點(dian)焊(han),點(dia������n)焊(han)后(hou)用10~20倍的(de)放大鏡一片(pian)一片(pian)地(di)對焊(han)接質量進(jin)行檢查.

改(gai)進工(gong)藝(yi)提(ti)高產(chan)品(pin)(pin)可靠(kao)性(xing)的(de)(de)另一(yi)個例子是獨石陶(tao)瓷電容器的(de)(de)包封工(gong)藝(yi)�����.以酒精為溶劑的(de)(de)環氧樹(shu)脂浸漬(zi)包封產(chan)品(pin)(pin)來說,由(you)于包裝的(de)(de)多孔性(xing),受(shou)潮(chao)聚(ju)積(ji)水分為銀離子的(de)(de)遷(qian)移提(ti)供了(le)條(tiao)件,造成產(chan)品(pin)(pin)短時(shi)間內大量失效.為了(le)提(ti)高獨石陶(tao)瓷電容器的��������(de)(de)防潮(chao)性(xing)能(neng),改(gai)用(yong)先涂覆GN521硅凝膠做底(di)漆,再(zai)包封環氧樹(shu)脂的(de)(de)工(gong)藝(yi).長(chang)期潮(chao)熱負(fu)荷試驗結果表明(ming),這種包裝工(gong)藝(yi)有很好的(de)(de)防潮(chao)性(xing)能(neng),產(chan)品(pin)(pin)的(de)(de)可靠(kao)性(xing)有明(ming)顯的(de)(de)提(ti)高.